- Home

- Age

- Brand

- American Art Decor (14)

- Antique (12)

- Coca Cola (11)

- Coca-cola (11)

- Dechane's (9)

- Esso (16)

- Eveready (7)

- Firestone (14)

- Goodyear (13)

- Handmade (21)

- Madura Coats Treads (11)

- Michelin (8)

- Mobil (13)

- Mobil Oil (11)

- Samurai (44)

- Shell (10)

- Signs By Jake (11)

- Texaco (17)

- Unknown (19)

- Winchester (27)

- ... (4531)

- Maker

- American (4)

- Antique (5)

- Hand Made (8)

- Handcrafted (2)

- Handmade (7)

- Ideal (5)

- Jackson Bangar (6)

- Kutani (3)

- Lyons (2)

- Noh Mask (shakumi) (2)

- Old Hickory (3)

- Picasso (2)

- Primitive (2)

- Primitive Artisanal (2)

- Satsuma (2)

- Signed (2)

- The Kings Bay (3)

- Thomas Annett (2)

- Unknown (49)

- Unknown Crafter (3)

- ... (4716)

- Material

- Theme

- 1950s (8)

- Advertising (3)

- Art (6)

- Automobiles (5)

- Bakery & Baking (3)

- Banking & Insurance (10)

- Bar & Club (4)

- Bar & Club, Novelty (4)

- Breweriana (9)

- Buddha (5)

- Circus & Carnival (4)

- Dairy (3)

- Distillery (4)

- Floral (5)

- Gas & Oil (68)

- Halloween (5)

- Nature (5)

- Portrait (6)

- Soda (21)

- Tires (3)

- ... (4649)

- Type

- Acoustic (9)

- Baskets (9)

- Bowls (11)

- Boxes (46)

- Furniture (14)

- Kitchen Equipment (25)

- Marquee Sign (13)

- Metal & Ironwork (31)

- Painting (190)

- Paintings (14)

- Plaque (20)

- Plaques / Signs (18)

- Pottery (13)

- Print (22)

- Sculpture (13)

- Sign (45)

- Signs (76)

- Street Sign (19)

- Tools (11)

- Wooden Sign (9)

- ... (4222)

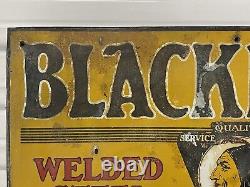

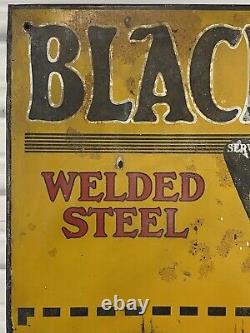

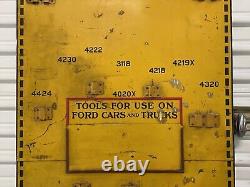

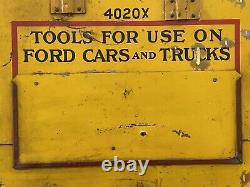

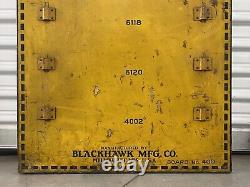

Very RARE Antique Old 1926 FORD Automobile BLACKHAWK Wrenches Milwaukee SIGN

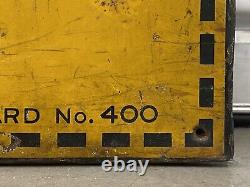

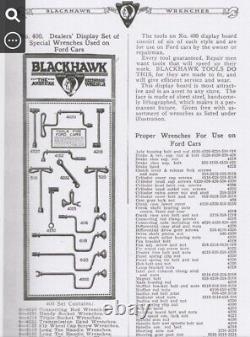

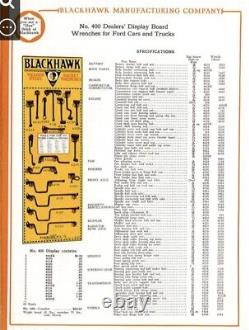

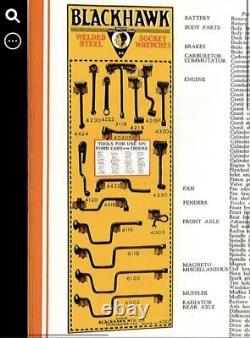

This is an incredible and Very RARE Antique Old FORD Automobile BLACKHAWK Wrenches Milwaukee Dealership SIGN, produced in 1926 by Blackhawk MFG. Blackhawk socket wrenches were at one point in time a very formidable competitor to Snap-On, MAC, and other well-known tool manufacturers. This very scarce sign was created in 1926, to display tools in a Ford automobile dealership to be used exclusively on Ford automobiles, which were Model T Fords at that time. It is referred to in several brochures by the company as Board No.

400 Please see the last few photos of this listing for references. This sign is painted in a bold taxicab yellow and black color scheme and depicts the early arrowhead Chief Blackhawk Indian logo which was popularly used by the company from 1919 - early 1930's and rendered with fine lithography on sheet steel, backed by wood.

This sign reads: BLACKHAWK: Welded Steel Socket Wrenches. TOOLS FOR USE ON FORD CARS AND TRUCKS. Approximately 22 1/2 x 69 5/8 x 1 inches. Good condition for nearly a century of age and storage, with expected scuffing, edge wear, dustiness, speckles of paint loss and oxidation throughout, etc. I have accurately identified this sign from a 1926 BLACKHAWK sales catalog, please see photo 23 & 24 in this listing.

This is the only one known to still exist on planet Earth. For the serious early Ford collector, who has everything except thi s. If you like what you see, I encourage you to make an Offer.Please check out my other listings for more wonderful and unique artworks! Certain types of early Blackhawk tools, in particular the sockets and extensions, were marked with a distinctive Arrowhead logo instead of the Blackhawk name. An example of this marking can be seen on the Arrowhead sockets. Blackhawk Manufacturing was a subsidiary of the American Grinder Corporation established to manufacture and market automotive tools.

American Grinder was incorporated in Milwaukee, Wisconsin in 1901. Items included several hand-crank grinders in four levels of quality from the little "Buddy" to the premium "Liberty".

They began making water and oil pumps for the military in 1914 and continued making water pumps after the war. C N & F W Jonas became affiliated with American Grinder between 1918 and 1919. The Jonas brothers had been in charge of marketing for Walden-Worcester and knew the automotive tools market. The brothers convinced Grinder to enter the tool market using their knowledge of Walden's latest work. The Court of Appeals determined the Blackhawk logo was likely to create confusion between the two brands and that American Grinder had intended to benefit from the similarity.

The logo was dropped but they retained their name. American Grinder reorganized in 1920 to provide needed capital for expansion of their wrench business. George Adam and Fred Mayer entered the company at this time. Then, Herbert Brumber became majority stakeholder in 1924. When it became apparent that the Blackhawk name was significantly more valuable than American Grinder, the Blackhawk name was adopted in 1925.The company acquired the Hydraulic Tool Company in 1927. It was during this period that Blackhawk partnered with Armstrong and had nothing to do with Chief Black Hawk at Fort Armstrong although "Chief and "Scout were brand names. From its founding in the early part of the 20th century, Blackhawk Manufacturing developed into one of the top producers of mechanic's tools, and its products were widely respected for their quality of design and production. Blackhawk's rapid innovation in the late 1920s and 1930s helped set the pace of development for the rest of the tool industry. This article will review the history of Blackhawk Manufacturing, and then illustrate the development of its tools from 1919 up through the mid 1950s.

Before beginning our section on the company's history, we'd like to note that 2019 was the 100-year anniversary of modern socket technology, ushered in by Blackhawk's introduction of heavy-duty interchangeable socket sets in 1919. An example of one of Blackhawk's earliest socket sets can be seen as the Blackhawk No.

Of course, the socket revolution itself had started some years earlier with the invention of the Auto-Clé pressed-steel sockets in 1904, and in the subsequent years Mossberg, Walden, Bay State, and others had proven the utility of interchangeable sockets for automotive service. But it was Blackhawk's heavy-duty machined and broached sockets that proved that interchangeable sockets could handle even the most difficult service jobs. Blackhawk Manufacturing began operations in 1919 as a subsidiary of the American Grinder Manufacturing Company, but to understand its story, it's helpful to go back a few years earlier to the founding of the parent company. American Grinder had been founded in 1910 by Leo Bethke, Frank Lueck, and Charles Krause, and the company operated in Milwaukee, Wisconsin, initially as the maker of a self-oiling hand grinder. With the impending end of the First World War, American Grinder's truck parts sales started slowing down, and the company looked for new lines of products.

This lead to the developments outlined in the next section. More information on American Grinder Manufacturing, including stories about their rather colorful early personnel, can be found in the Actuant History noted in our References section. Developing a New Product Line. In late 1918 the war was drawing to a close, and American Grinder was interested in developing new product lines to make up for the slowing sales of truck parts.

The company had recently hired the C. Jonas firm as sales agents, and the Jonas brothers had a very specific suggestion for American Grinder. The Jonas firm had been the sales agents for Walden-Worcester's west coast region from 1914 to 1918 and were therefore very familiar with Walden's line of automotive socket wrenches and socket sets. The Jonas brothers suggested that American Grinder should replicate substantially all of Walden's line of automotive tools, and apparently even went so far as to suggest "Blackhawk" as the trade name. Our information for this section comes from a number of reports of later court proceedings after Walden-Worcester sued American Grinder and the Jonas brothers - we'll have more on that later. In the context of the 1918 automotive tools market, developing a line of tools to compete with Walden looked like a good business choice. See our article on Walden-Worcester for more background on the company. Hence American Grinder followed the Jonas brothers' recommendation and began planning to offer a line of both fixed socket wrenches and interchangeable socket sets. Although Walden served as the primary starting point for the tool line, we can offer evidence that American Grinder also studied the socket tools produced by the Frank Mossberg Company, as the Blackhawk 911 rachet is much closer to Mossberg's well-known Model 350 Rachet than to any of Walden's models. It's probably safe to assume that American Grinder would have reviewed the existing state of the socket market, to make sure that they didn't miss any important features or run afoul of patent restrictions. One question remains regarding the extent to which the Jonas brothers may have influenced the socket technology used for the new interchangeable socket sets. It's possible that Walden may have shown prototypes of the new line to the Jonas brothers while they were still sales agents for Walden, with this information then being passed on to American Grinder. But it's also possible that American Grinder would have found it simpler from a production standpoint to use the same type of heavy-wall machined sockets for both fixed-socket wrenches and interchangeable sets, with the only difference being the type of connection to the drive tool or rod. In any event, Blackhawk's new socket sets ended up with heavy-wall machined and broached sockets, which provided a major improvement in strength over the prevailing pressed-steel sockets. This was a critical factor in gaining rapid acceptance for the new sets, and it would be very interesting to find additional information in this area. The Formation of Blackhawk Manufacturing. Once the decision had been made to develop the line of automotive tools, American Grinder formed a new wrench division and promoted one of their employees, Joseph Johnson, as manager (or foreman) of the division. As the company already had substantial expertise at manufacturing, it didn't take long to tool up the factory for the new product line. By May of 1919 the wrench division had been named. And by the end of the month Blackhawk socket sets and socket wrenches were available for sale.But even before the May 31 date, Blackhawk's agents C. Jonas had started announcing the new line in the trade press. An announcement for the new line of tools, as published on page 84 of the April, 1919 issue of.

The illustration in this announcement shows only fixed-socket wrenches, tools that were already very familiar to the automobile repair industry. However, advertisements would soon appear for the interchangeable socket sets in Blackhawk's new line. A notice published on page 154 of the same April, 1919 issue of. Which provides a concise summary of the association of the C. Jonas firm with American Grinder Manufacturing.

The text mentions the prior association of the Jonas brothers with Walden-Worcester, and goes on to note that American Grinder had retooled their 45,000 square foot factory to manufacture the new line of socket wrench tools. This notice is remarkable in that it preannounces the name "Blackhawk" even before the company had started using it! The initial product line consisted of five models of 1/2-drive interchangeable socket sets, the Nos. 2, 4, 6, 8, and 10 "Combination Sets", plus numerous fixed socket wrenches designed to replicate Walden's extensive line. An example of one of these early sets can be seen as the Blackhawk No. It's important to emphasize that the sockets in these early Blackhawk sets were of heavy-wall construction, machined and cold-broached from bar steel.This was the technology that would dominate socket construction in the 1920s and 1930s. Up to this point cold-broached sockets had been offered only in relatively light-duty sets from Wil B.

Sedley so the heavy-wall interchangeable sets from Blackhawk were an important milestone. A notice published on page 52 of the June 26, 1919 issue of. Providing a description of one of the new Blackhawk socket sets. The text notes the inclusion of hex and square sockets with a ratchet, brace, universal, and extension as drive tools. Although not mentioned in the text, this would have been the Blackhawk No.

Blackhawk placed a number of advertisements for its new line of tools during the spring and summer of 1919, in trade publications such as the. One of the earliest advertisements for Blackhawk tools, as published on PAGE 103 of the May 22, 1919 issue of. The illustration shows all five models of Blackhawk's early socket sets, along with a display board of fixed socket wrenches for Ford service. The Jonas brothers had been the sales agents for Walden-Worcester previously, and their involvement with American Grinder was a major factor in a later lawsuit by Walden. This same ad appeared in the June 5 and June 19 issues of.And in the June 25 issue of. The early Blackhawk socket sets were available in five different models, numbered from smallest to largest as Nos. 2, 4, 6, 8, and 10. A table of the set contents can be found in the section on Socket Sets.

Another early ad for Blackhawk socket sets, as published on the July 1, 1919 issue of the. The illustration shows three of Blackhawk's interchangeable socket sets, as well as a display board of fixed socket wrenches. Another early ad for Blackhawk tools, as published on the July 3, 1919 issue of.

This advertisement emphasizes the fixed-socket part of Blackhawk's line, and the illustration shows a sampling of the many Blackhawk fixed-socket wrenches and specialty tools. 6 "Combination Set" socket set is illustrated just below the center text inset. An example of this set can be seen as the Blackhawk No. An advertisement for the Blackhawk No. 8 socket set, as published in the August 10, 1919 issue of. The set in the illustration is a Blackhawk No. 8 "Combination Set", which includes a ratchet, a sliding Tee handle, two extensions, a universal, 16 hexagon sockets, three square sockets, and other miscellaneous tools.Note again that the text identifies C. Jonas as the sales agents for American Grinder near the bottom of the advertisement.

Some subtle details in the illustration add further evidence for the Walden origin of the early Blackhawk tools. If you look closely at the extensions in the socket set, the drive stud end has a pin sticking out from both sides, to act as a stop for the socket. This was an uncommon production detail known to have been used by Walden, and an example can be seen in the Early Walden 1139 Extension.Blackhawk is not known to have used stop-pins in any of its actual production, suggesting that the illustrations were probably prepared from early prototypes of the tools. The Blackhawk socket sets and fixed socket wrenches appear to have been highly successful products right from the beginning. Although it's generally difficult to get good estimates of sales volumes of older tools, we can make some qualitative judgements based on the observed frequency of items today. As part of the collection activities to support this article, within the past few years we have been able to round up examples of four of the five early Blackhawk socket set models, and with multiple examples for some of the sets.

Based on these observations, the early Blackhawk sets in wooden boxes are not especially rare, and although much less common than the sets made by Mossberg (the leading maker of pressed-steel socket sets), Blackhawk sets are probably more common than those of the numerous other makers. In addition to being commercially successful, Blackhawk's interchangeable socket sets were important historically as the first line to offer heavy-duty machined and broached sockets for automotive service, thereby ushering in the modern era of socket tools. The decade leading up to 1919 had seen automotive socket sets develop into a thriving (even booming) industry, lead by makers such as Mossberg, Walden, Bay State, Syracuse Wrench, and numerous others. These earlier makers had proven the convenience and utility of interchangeable sockets, but since the sets were based on relatively weak pressed-steel sockets, they lacked the strength needed for everyday use by professional mechanics. Blackhawk's heavy-wall sockets changed all that - mechanics could now wholeheartedly embrace interchangeable sockets, and the socket industry entered a new phase of explosive growth.

Of course there were many improvements to be added later - alloy steel sockets, hot-forging and hot-broaching, better drive tools such as flex-head handles, fine-tooth ratchets, and so on. But Blackhawk's sockets were a major milestone, and readers interested in tool history may want to mark May 31, 2019 on their calendars as the 100th Year Anniversary of modern socket technology.

By early 1920 two employees of Blackhawk and American Grinder, Joseph Johnson and William Seidemann, had left the company to start their own business. Additional information about their new business can be found in our article on the Snap-On Wrench Company. The sudden appearance of a new competitor must have come as a great shock to Walden-Worcester, especially since Blackhawk's new line of fixed socket wrenches replicated practically all of Walden's models. Even more damaging was the presence of a full line of heavy-duty interchangeable socket sets, as these effectively stole the thunder from Walden's introduction of its own line of interchangeable socket sets. Walden's socket sets finally came out in 1920 - for more information, see our section on Walden Sockets and Drive-Tools. The final blow was the realization that the Jonas Brothers, who until 1918 had been sales agents for Walden, were now the agents for the Blackhawk line. A further claim of patent infringement was later added to the complaint, based on Blackhawk's version of the Nut-Holding Speeder originated by Walden. A notice of court proceedings against American Grinder, as published on page 349 of the August 11, 1921 issue of. The text provides some details of the court action filed by Walden-Worcester against American Grinder Manufacturing and its sales agents, the C. New Investors and A Treasurer. In 1920 American Grinder found itself in need of additional funds, possibly as a result of the impending (if not ongoing) Walden litigation noted above.The need for additional capital was filled by an investment by Herbert Brumder and two siblings, plus others related by marriage. The Brumders were the sons of George Brumder, a well-known Milwaukee businessman who had built a German-language publishing business during the late 19th century. In addition to becoming an investor, Herbert Brumder signed on to become the treasurer of American Grinder. A notice of the reorganization of American Grinder, as published on page 885 of the April 3, 1920 issue of.

The text notes the recapitalization of the company with investments by the Brumder siblings and their in-laws. This notice incorrectly names Herman Brumder as treasurer, instead of Herbert Brumder.

Another notice regarding the recapitalization of American Grinder, as published on page 98 of the May 15, 1920 issue of the. This notice correctly names Herbert Brumder as company treasurer.Both notices cite rapid growth as the reason for the recapitalization, though this may have been a euphemism. The Jonas Brothers are also cited as the sales agents. Within a few years American Grinder again needed more capital, and by 1924 Herbert Brumder had become the major stockholder and company president.

Development Through the Mid 1920s. With the early success of its interchangeable socket sets Blackhawk became the leading producer of heavy-duty socket tools through at least the mid 1920s. Competition came quickly though, first from Walden-Worcester, who by mid 1920 was offering a full line of heavy-duty interchangeable socket sets in wooden boxes, comparable to the Blackhawk line. Within a year or two the fast-growing Snap-On Wrench Company also became a strong competitor. Throughout the 1920s, Blackhawk, Snap-On Wrench, and Walden fought for control of the socket market, with each company trying to outdo the others with innovations and improvements.Snap-On appears to have been the first with a larger 5/8 drive size, but Blackhawk responded by leaping to 3/4-drive and then 7/8-drive. In 1925 Walden topped both companies with a line of 1 inch hex drive tools, and also became the first maker to offer interchangeable sockets in alloy (chrome-nickel) steel. Despite the fierce competition, the rapidly growing market ensured that all three companies did well in this era.

A Name Change and More Competition. By 1925 Blackhawk Manufacturing had become highly successful, with the result that the Blackhawk name had become much more widely recognized than that of its somewhat obscure parent, American Grinder Manufacturing. Accordingly, in 1925 American Grinder changed its name to Blackhawk Manufacturing. The name change is noted in the August 1925 issue of. In an advertisement for Blackhawk Socket Wrenches.

Note the parenthetical Formerly American Grinder Mfg. " below the larger "Blackhawk Mfg.The latter part of the 1920s saw continued growth for Blackhawk, but also greatly increased competition. New makers entering the socket market included Cornwell (1926), Bonney (1927), and Plomb (1927), all of whom provided tools primarily for professionals.

By 1928 Duro/Indestro and Hinsdale Manufacturing, two low-cost, high-volume manufacturers, had also become major competitors in the socket market. In 1927 Blackhawk saw an opportunity to expand its product lines into hydraulic jacks and acquired the Hydraulic Tool Company.

Over the next decade Blackhawk became a leading supplier of hydraulic jacks for automotive service, and expanded into new areas with innovative products for lifting and pushing in constrained areas. During the 1930s Blackhawk's engineers (Edward Pfauser and others) developed and patented various hydraulic devices.

The hydraulic line provided an additional market for Blackhawk and proved to be important for the later history of the company. However, as this site is primarily interested in hand tools, we can't offer much information on the hydraulic products. Lock-On Socket Tools and Continued Innovation.

In the late 1920s Blackhawk began developing a new high-end line of socket tools featuring an innovative "Lock-On" locking mechanism. This ushered in a period of tremendous innovation during the 1930s and 1940s, lead by their engineers Edward Pfauser, Sigmund Mandl, and others. During this time Blackhawk received numerous patents for wrench and ratchet designs and socket locking devices. Among the tools developed were the "Lock-On" locking sockets, gearless ratchets, ratchet adapters, reversible handles, and specialty tools such as the model 151 drain-plug wrench. Out of the Hand Tool Business. Brumder succeeded his father Herbert as president of Blackhawk Manufacturing. The younger Brumder recognized that the company faced some challenges -- from the late 1940s onward Blackhawk's line of socket tools had been becoming less competitive and losing market share. The loss of market share is based on observations that Blackhawk's later handle style is much less common than the earlier "Gripline" tools. Brumder began planning and implementing major changes for the company. The first changes were visible in the Blackhawk catalog W-101 for 1953, with some copies printed in December of 1952. This catalog edition was markedly different from the previous W-51 and earlier catalogs.In particular, catalog W-101 offered many new types of tools not previously listed by Blackhawk, including pliers, screwdrivers, gear pullers, auto-body tools, and even soldering irons. The new catalog positioned Blackhawk as a full-service tool brand, rather than as a socket tools and wrenches specialist. By the early 1950s most of Blackhawk's competitors operated as full-service vendors of mechanic's tools, including such companies as Armstrong, Bonney, Cornwell, Duro/Indestro, Herbrand, MAC, New Britain, Plomb Tool (Proto brand), Snap-on, and J. Expanding Blackhawk's product offerings put them on a more equal footing with their competitors, although since most of the new products were rebranded contract production with lower margins, the larger product line may not have increased the business profits that significantly.

By 1955 the full extent of Brumder's plan had become clear. New Britain crated up all of Blackhawk's production equipment and moved it back to their base in Connecticut. Blackhawk as a division of New Britain continued as a full-line supplier of automotive service tools, and most of the older Blackhawk socket wrench line remained in production for some time. Gradually though, some of the more distinctive products were dropped.

In particular, Lock-On tools in 1/2-drive and all 7/16-drive tools had been discontinued by 1963. Eventually New Britain Machine folded, and its assets (including the Blackhawk and Husky trademarks) were acquired by The Stanley Works. Stanley today continues to use the Blackhawk name for one of its product lines. Blackhawk Manufacturing to Applied Power Industries to Actuant. After the sale of the hand tools division, Blackhawk Manufacturing retained its line of hydraulic jacks and other hydraulic products and focussed on building out that line of products.

Within a few years the company changed its name to Applied Power Industries to better reflect the new company business lines, and then changed its name again to Actuant Corporation. After many decades of growth and acquisitions (and another name change), the company continues in operation today as the EnerPac Tool Group.